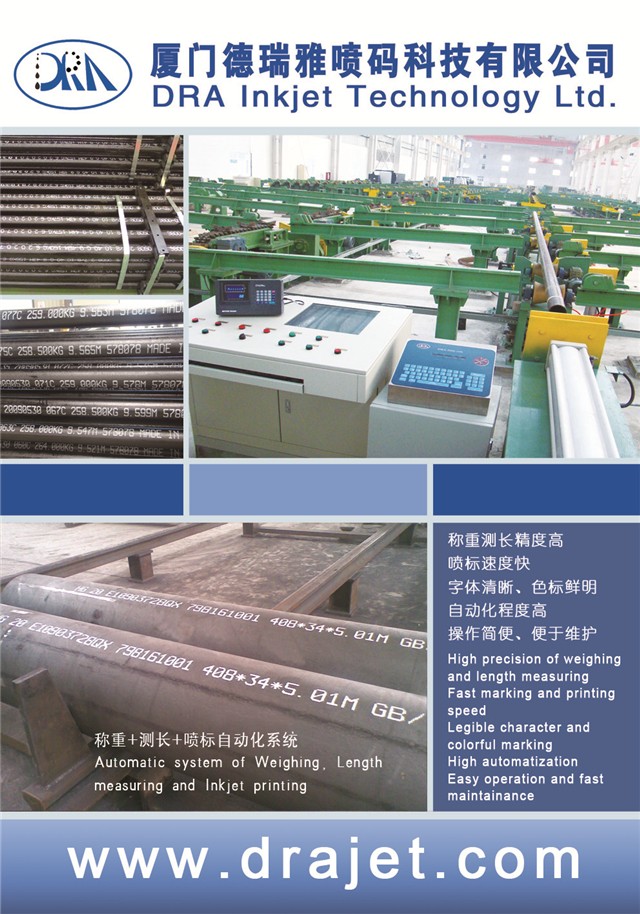

Steel tube marking machine / Weighing and length measuring system

詳細說明

Steel tube weighing, length measuring and marking machine combines machinery, electricity, automation; integrates measuring, marking and other functions in a fully automated system. Has the advantage of high precision weighing and measuring length, high marking speed, clear fonts, bright color and automation. In order to improve the welded steel tube precision of weighing and measuring length, DRA compared several weighing and measuring length systems, found out their shortcomings and requirements to design a simple, convenient and high-precision system for weighing and measuring length. Weighing, measuring length, oiling, marking can be carried out at the same time with automation.

The system provides various alarm functions.

The system concise description.

The whole system control process as follows:

1. The system passes a single steel tube through the cylinder and turns into the weighing platform;

2. The weight data of the steel pipe are collected on the weighing bracket and the material is sent to the waiting measuring station by lifting the material poking mechanism through the cylinder;

3. The system sends a single steel tube to the measuring track station;

4. After measuring length, the steel pipe is sent to the oiler for oiling;

5. After the steel pipe has been oiled, the printing machine begins to print on the steel pipe;

6. After the printing is done, the system will send the steel pipe to the drying and packing station.

previous item: DRA 9000 SERIES

next item: Spare parts and related equipments

關閉返回

關閉返回